- RFQ

- BOM

-

Contact Us

Tel: +86-0755-83501315

Email: sales@sic-components.com

- Chinese

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

Dc Capacitor Types

1. Introduction

In the realm of electronics, direct - current (DC) capacitors play a crucial and often under - appreciated role. These components are essential for the proper functioning of numerous electronic devices and systems that rely on DC power. From smartphones and laptops to complex industrial control systems, DC capacitors contribute significantly to energy storage, signal processing, and power supply stability. This comprehensive article will explore every aspect of DC capacitors, including their basic principles, types, applications, and key considerations in their use.

2. Basic Principles of DC Capacitors

2.1 Structure and Composition

A DC capacitor is typically composed of two conductive plates separated by an insulating material known as a dielectric. The conductive plates are usually made of metals such as aluminum or tantalum, while common dielectric materials include ceramic, electrolytic substances, and various types of films. When a DC voltage is applied across the capacitor, electrons accumulate on one plate, creating a negative charge, while the other plate loses electrons and becomes positively charged. This separation of charges generates an electric field between the plates, which stores electrical energy.

2.2 Charging and Discharging

Charging Process: When a DC capacitor is connected to a DC power source, it begins to charge. Electrons flow from the negative terminal of the power source to one plate of the capacitor, while electrons are pulled away from the other plate towards the positive terminal of the power source. As the charging progresses, the voltage across the capacitor gradually increases. The charging current is high at the beginning and decreases over time. Once the voltage across the capacitor reaches the same level as the applied DC voltage, the capacitor is considered fully charged, and the charging current drops to zero. Mathematically, the charge (Q) stored in a capacitor is related to the capacitance (C) and the voltage (V) by the formula Q = CV.

Discharging Process: When a load is connected across a charged DC capacitor, the capacitor starts to discharge. The stored electrons flow through the load, creating a current. As the electrons move, the charge on the capacitor plates decreases, and so does the voltage across the capacitor. The capacitor continues to discharge until all the stored energy is depleted, and the voltage across it drops to zero.

2.3 Blocking DC Current

One of the most important characteristics of a DC capacitor is its ability to block the flow of direct current once it is fully charged. In a steady - state DC circuit, after the capacitor has reached its maximum charge, there is no further movement of electrons through the capacitor because there is no potential difference to drive them. This property makes DC capacitors useful for isolating different parts of a circuit from the DC power supply while allowing other electrical signals to pass or be processed.

3. Types of DC Capacitors

3.1 Electrolytic Capacitors

Construction and Characteristics: Electrolytic capacitors consist of a metal anode, a liquid or solid electrolyte, and a cathode. They offer high capacitance values in a relatively small size, making them suitable for applications that require large amounts of charge storage, such as power supplies. However, they are polarized, meaning they have a specific positive and negative terminal. Connecting them with the wrong polarity can lead to overheating, electrolyte leakage, or even explosion. Electrolytic capacitors also have a relatively high equivalent series resistance (ESR) compared to some other types, which can cause power losses in the form of heat.

Applications: Commonly used in power supply circuits to smooth out voltage ripples, providing a more stable DC output. They are also found in audio amplifiers for coupling signals between different stages of the amplifier, and in timing circuits where their large capacitance values help set time constants.

3.2 Ceramic Capacitors

Construction and Characteristics: Ceramic capacitors use ceramic materials as the dielectric. They come in a wide range of capacitance values, from very small values in the picofarad range to larger values in the microfarad range. Ceramic capacitors have excellent temperature stability, low ESR, and can operate at high frequencies with minimal signal loss. They can be either polarized or non - polarized, with non - polarized types being more common for general - purpose applications.

Applications: Widely used as bypass capacitors in electronic circuits to filter out high - frequency noise from power lines, ensuring a clean power supply for sensitive components. They are also used in high - frequency filter circuits, such as those in radio frequency (RF) applications, and for coupling signals in circuits where maintaining signal integrity at high frequencies is crucial.

3.3 Film Capacitors

Construction and Characteristics: Film capacitors are made by sandwiching a thin dielectric film between two conductive layers, which are often metalized films. They have low ESR, good stability over time and temperature, and can handle high voltage ratings. Film capacitors are non - polarized, allowing them to be used in a variety of AC and DC applications without concerns about polarity.

Applications: Commonly employed in high - frequency circuits, power supplies where stable performance and low losses are required, and audio applications to improve sound quality by reducing distortion and noise. They are also used in circuits that need to withstand high voltage spikes or transient events.

3.4 Tantalum Capacitors

Construction and Characteristics: Tantalum capacitors use tantalum metal as the anode and an electrolyte. They offer high capacitance values in a small physical size, similar to electrolytic capacitors, but with better stability and lower ESR. Tantalum capacitors are polarized and are known for their high reliability and long lifespan, making them suitable for applications where consistent performance is critical.

Applications: Often used in high - frequency circuits as bypass capacitors, in portable electronic devices where space is limited but high capacitance is needed, and in timing circuits due to their stable

capacitance characteristics.

4. Applications of DC Capacitors

4.1 Power Supply Systems

Ripple Filtering: In DC power supplies, capacitors are used to filter out the ripple voltage, which is the small AC - like variation in the DC output. By storing and releasing energy, DC capacitors smooth out these fluctuations, providing a more stable DC voltage to power the connected circuits. For example, in a simple rectifier circuit that converts AC to DC, large - value electrolytic capacitors are placed at the output to reduce the ripple and ensure a clean DC supply for the load.

Energy Storage: DC capacitors also act as energy storage devices in power supplies. They can supply additional current during peak load demands, preventing voltage drops and ensuring continuous operation of the circuit. In battery - powered devices, capacitors can help buffer the power supply, stabilizing the voltage when the battery's output voltage may vary.

4.2 Signal Processing

Coupling: Capacitors are used to couple signals between different stages of an amplifier or other electronic circuits. They block the DC component of the signal, allowing only the AC signal to pass through. This is important for preventing the DC bias of one stage from affecting the next stage while ensuring that the desired AC audio, video, or other types of signals are transmitted without distortion. For instance, in an audio amplifier, ceramic or film capacitors are commonly used for coupling the audio signal between amplifier stages.

Decoupling: Also known as bypassing, decoupling capacitors are placed near integrated circuits (ICs) and other sensitive components to provide a local energy source. They filter out high - frequency noise from the power supply lines, ensuring that the ICs receive a clean and stable power supply. This helps improve the overall performance and reliability of the circuit by reducing the impact of power supply fluctuations on the operation of the components.

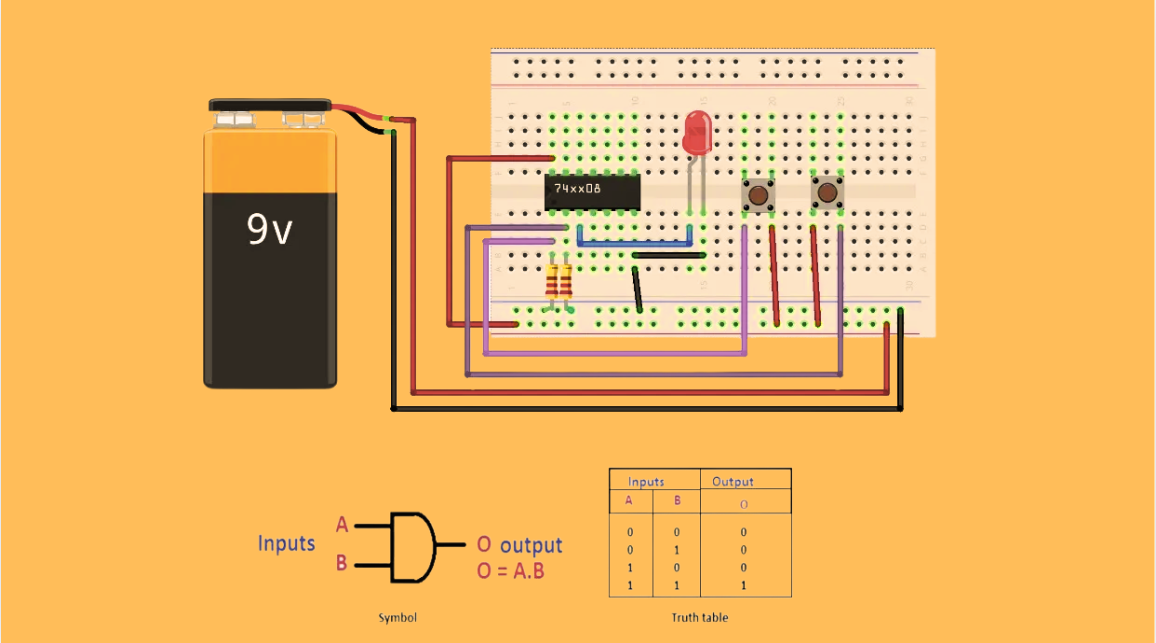

4.3 Timing Circuits

In circuits that rely on precise timing, such as oscillators and delay circuits, DC capacitors work in conjunction with resistors to set the time constants. The time constant (τ) of an RC (resistor - capacitor) circuit is calculated as τ = RC. By adjusting the values of the resistor and capacitor, engineers can control the frequency of oscillation in an oscillator circuit or the duration of a delay in a timing circuit. For example, in a 555 timer - based oscillator, the choice of capacitor and resistor values determines the output frequency of the generated signal.

5. Key Considerations in Using DC Capacitors

5.1 Capacitance Value

Selecting the appropriate capacitance value is crucial for the proper functioning of the circuit. The required capacitance depends on the specific application. For example, in a power supply ripple - filtering application, a larger capacitance value is generally needed to effectively reduce the ripple voltage. In a high - frequency coupling application, a smaller capacitance value may be sufficient to pass the desired high - frequency signals while blocking lower frequencies.

5.2 Voltage Rating

The voltage rating of a DC capacitor must be higher than the maximum voltage it will encounter in the circuit. Exceeding the voltage rating can lead to dielectric breakdown, causing the capacitor to fail. A safety margin of at least 20 - 30% above the expected operating voltage is often recommended to ensure reliable operation and prevent premature failure.

5.3 Polarity (for Polarized Capacitors)

As mentioned earlier, polarized capacitors such as electrolytic and tantalum capacitors must be connected with the correct polarity. Incorrect polarity can not only damage the capacitor but also pose a safety risk. Always check the markings on the capacitor to identify the positive and negative terminals before installation.

5.4 Equivalent Series Resistance (ESR)

ESR represents the internal resistance of the capacitor. A lower ESR is desirable in many applications as it reduces power losses and heat generation within the capacitor. In high - current or high - frequency applications, choosing a capacitor with a low ESR can significantly improve the circuit's efficiency and performance.

5.5 Temperature and Environmental Conditions

Capacitors have specified operating temperature ranges. Operating a capacitor outside of its rated temperature range can affect its capacitance value, lifespan, and overall performance. In addition, environmental factors such as humidity and exposure to chemicals can also impact the performance and reliability of capacitors. For harsh environments, special - purpose capacitors designed to withstand such conditions should be selected.

6. Conclusion

DC capacitors are indispensable components in the world of direct - current electronics. Their ability to store and release energy, block DC current, and perform various functions in different circuits makes them essential for the design and operation of a wide range of electronic devices and systems. By understanding the basic principles, types, applications, and key considerations related to DC capacitors, engineers and electronics enthusiasts can make informed decisions when selecting and using these components, ensuring the optimal performance and reliability of their electronic designs. As technology continues to advance, the importance of DC capacitors in enabling new and innovative electronic applications will only grow.

https://www.sic-components.com/capacitors

Hot Products

View MoreRelated Blogs

2000+

Daily average RFQ Volume

30,000,000

Standard Product Unit

2800+

Worldwide Manufacturers

15,000 m2

In-stock Warehouse

Wishlist (0 Items)

Wishlist (0 Items)