- RFQ

- BOM

-

Contact Us

Tel: +86-0755-83501315

Email: sales@sic-components.com

- Chinese

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

How to choose the right LED driver?

Selecting the appropriate LED driver is crucial for ensuring the optimal performance, longevity, and safety of LED lighting systems. This article aims to offer a comprehensive, step - by - step guide on the key factors to consider when choosing an LED driver. By understanding these factors, readers can make well - informed decisions tailored to their specific application requirements, whether for residential, commercial, or industrial use.

Understand Your LED Requirements

LED Type and Quantity

LEDs come in various types, each with distinct characteristics that significantly influence driver selection. High - power LEDs, often used in outdoor lighting like streetlights or large - scale commercial signage, demand drivers capable of delivering substantial current and handling high power levels. On the other hand, small - signal LEDs, typically found in indicator lights or small electronic devices, require less power and can be driven by simpler, lower - capacity drivers.

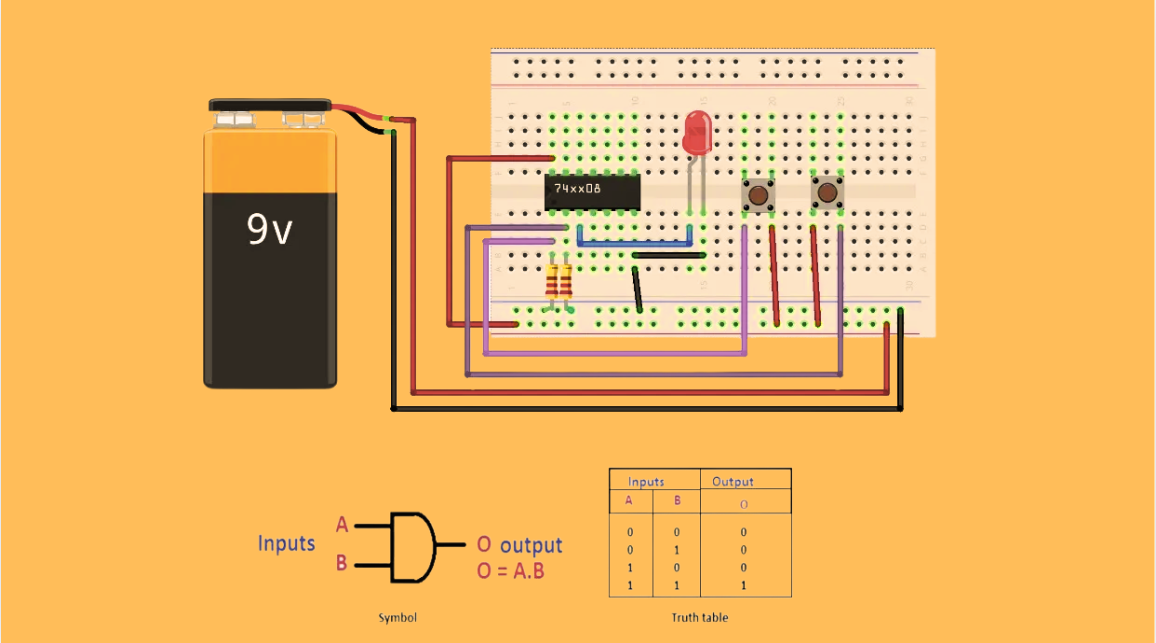

The number of LEDs in a circuit and their connection configuration (series, parallel, or a combination) are also critical considerations. In a series - connected LED circuit, the same current flows through each LED, and the total voltage drop across the LEDs is the sum of their individual forward voltages. Parallel - connected LEDs share the same voltage, but the total current is divided among them. A combination configuration offers more flexibility but also requires a more sophisticated driver to manage current and voltage distribution accurately. Understanding these configurations helps determine the driver's output current and voltage requirements precisely.

LED Specifications

The forward voltage (Vf) of LEDs is a fundamental specification that directly impacts the driver's voltage output. LEDs have a specific Vf at which they operate efficiently, and the driver must supply a voltage sufficient to overcome this drop while maintaining a stable current. Deviating from the optimal Vf can lead to inconsistent brightness, reduced efficiency, or even LED damage.

The recommended driving current for LEDs is equally important. Each LED has a maximum rated current beyond which it may overheat and suffer premature failure. The driver must be able to deliver a stable current within the LED's recommended range to ensure consistent performance and longevity. Other relevant LED specs, such as luminous efficacy (the amount of light output per unit of electrical power) and color temperature, can also influence driver choices. For example, in applications where color accuracy is critical, such as in photography studios or museums, drivers that can maintain a stable current and minimize fluctuations are preferred to preserve the LED's color - rendering properties.

Consider Power Input and Output

Input Power Type

LED drivers can operate with either AC or DC input power, each with its own set of advantages and disadvantages. AC - input drivers, also known as off - line drivers, are commonly used in household and commercial lighting applications where the primary power source is the electrical grid. They offer convenience as they can directly connect to the AC mains, eliminating the need for an additional DC power supply. However, AC - input drivers often require more complex circuitry for rectification, filtering, and power factor correction, which can increase their cost and size. Additionally, they may have lower overall efficiency compared to DC - input drivers.

DC - input drivers, on the other hand, are more efficient and simpler in design. They are ideal for applications where a DC power source is already available, such as in battery - operated devices, automotive lighting, or systems powered by solar panels. DC - input drivers can directly convert the DC voltage to the appropriate level for the LEDs, reducing energy losses. However, they may require additional components to ensure compatibility with the DC source and may not be suitable for applications that rely on the AC grid. When choosing between AC - input and DC - input drivers, consider the available power source, application requirements, and the trade - offs between efficiency, complexity, and cost.

Input Voltage Range

Matching the driver's input voltage range with the available power supply is essential for reliable operation. Voltage fluctuations in the power supply can cause instability in the driver's output, leading to inconsistent LED performance, flickering, or even damage to the LEDs and the driver itself. Different types of LED drivers are designed to operate within specific input voltage ranges, such as 100 - 240V AC for universal AC - input drivers or 12 - 24V DC for low - voltage DC - input drivers. It is crucial to select a driver whose input voltage range can accommodate the expected variations in the power supply, especially in regions with unreliable or fluctuating grid power.

Output Power and Current

Calculating the required output power of the LED driver is straightforward once you know the number and power consumption of the LEDs. Multiply the number of LEDs by their individual power ratings to determine the total power requirement. The driver must be able to supply at least this amount of power to ensure the LEDs operate at their optimal brightness.

Equally important is the driver's ability to provide a stable and appropriate output current. Constant - current drivers are commonly used for LEDs because they maintain a consistent current flow through the LEDs, regardless of voltage variations. This is crucial for ensuring uniform brightness and preventing LED overheating. Constant - voltage drivers, on the other hand, are suitable for applications where LEDs are connected in parallel and require a stable voltage supply. Understanding the LED configuration and choosing the right type of driver (constant - current or constant - voltage) based on it is key to achieving reliable and efficient LED operation.

Evaluate Driver Features

Dimming Capabilities

LED drivers offer various dimming techniques, each with its own advantages and disadvantages. Pulse - width modulation (PWM) dimming is a popular method that controls the brightness of LEDs by rapidly switching the current on and off at a high frequency. It provides excellent color quality and flicker - free operation, making it suitable for applications where color accuracy and visual comfort are important, such as in residential and commercial lighting. However, PWM dimming may require more complex control circuitry.

Analog dimming, on the other hand, adjusts the LED brightness by varying the current continuously. It is a simpler and more cost - effective dimming method but may introduce some color shift and flicker, especially at lower brightness levels. 0 - 10V dimming is a widely used standard for commercial lighting applications. It allows for easy integration with building automation systems and provides smooth dimming over a wide range. TRIAC dimming, commonly used in household dimmers, is compatible with existing incandescent dimmer switches but may cause flicker and compatibility issues with some LED drivers. When choosing a dimming feature, consider the application's requirements, such as the need for smooth dimming, energy savings, and compatibility with existing control systems.

Protection Features

Essential protection features in LED drivers safeguard the LEDs and the driver itself from damage caused by electrical faults or abnormal operating conditions. Over - current protection limits the current flowing through the LEDs to prevent overheating and damage. Over - voltage protection shuts off the driver when the input or output voltage exceeds a safe level, protecting the LEDs from excessive voltage. Under - voltage protection ensures that the driver does not operate when the input voltage is too low, which could lead to unstable LED performance.

Short - circuit protection detects and isolates short circuits in the LED circuit, preventing damage to the driver and the LEDs. Thermal protection monitors the driver's temperature and activates when it reaches a critical level, shutting down the driver to prevent overheating and potential fire hazards. Selecting a driver with reliable protection features is crucial for ensuring the long - term reliability and safety of the LED lighting system.

Efficiency and Power Factor

Driver efficiency refers to the ratio of the useful power output (the power delivered to the LEDs) to the total power input. A more efficient driver consumes less energy, reducing operating costs and minimizing heat generation. Factors that influence driver efficiency include the type of conversion topology (such as buck, boost, or flyback converters) and the quality of components used. Choosing a driver with a high - efficiency conversion topology and high - quality components can significantly improve the overall energy efficiency of the LED lighting system.

Power factor is a measure of how effectively an AC - input LED driver uses the electrical power from the grid. A high power factor (close to 1) indicates that the driver draws power in a more efficient manner, reducing power losses in the electrical grid and improving the overall efficiency of the lighting system. In commercial and industrial applications, where large numbers of LED drivers are used, a high power factor is often required to meet energy - efficiency standards and reduce the impact on the electrical grid. When selecting an AC - input LED driver, look for one with a high power factor rating to minimize energy costs and comply with regulations.

Consider Physical and Environmental Factors

Size and Form Factor

The physical size and form factor of the LED driver are important considerations, especially in applications with limited space. In recessed lighting fixtures, for example, the driver must fit within the confined space of the housing without interfering with the installation of other components. Compact electronic devices also require small - sized drivers that can be easily integrated into their design.

LED drivers are available in various packages, such as surface - mount devices (SMD), through - hole devices (THD), and module - type drivers. SMD drivers are small and suitable for high - density circuit board designs, while THD drivers are larger but may be easier to handle during assembly. Module - type drivers offer a more integrated solution, often with built - in heat sinks and connectors, making them convenient for installation in specific applications. Ensure that the driver's size and form factor are compatible with the available space and the overall design of the LED lighting system.

Thermal Management

Thermal management is crucial for LED drivers as excessive heat can degrade driver performance and reduce its lifespan. Power losses within the driver, caused by factors such as resistance in components and inefficient power conversion, generate heat. High - current operation also contributes to increased heat generation. To dissipate this heat effectively, LED drivers may incorporate heat sinks, thermal pads, or built - in cooling fans.

Heat sinks are metal structures that increase the surface area for heat dissipation, allowing the heat to be transferred to the surrounding environment more efficiently. Thermal pads are used to improve the thermal conductivity between the driver components and the heat sink. Built - in cooling fans actively circulate air to cool the driver, providing enhanced cooling in high - power applications. Proper installation and ventilation are also essential for efficient heat dissipation. Ensure that the driver is installed in a well - ventilated area and that there is sufficient clearance around it to allow air to flow freely.

Environmental Conditions

The environmental conditions in which the LED driver will operate can significantly affect its performance and reliability. Temperature, humidity, dust, and vibration are common environmental factors to consider. In outdoor applications, for example, the driver must be able to withstand extreme temperatures, rain, and dust. Drivers rated with an Ingress Protection (IP) code, such as IP65 or IP67, are suitable for outdoor or wet - location installations as they provide protection against water and dust ingress.

In industrial environments, where there may be high levels of vibration or electromagnetic interference, drivers with robust mechanical and electrical designs are required. When choosing an LED driver, consider the specific environmental conditions of the application and select a driver that is rated and designed to operate reliably in those conditions. Protecting the driver from environmental hazards, such as using appropriate enclosures or covers, is essential for ensuring its long - term operation.

Cost and Availability

Cost Considerations

The cost of LED drivers is influenced by several factors, including brand, features, quality, and quantity. Well - known brands often command higher prices due to their reputation for quality, reliability, and customer support. Drivers with advanced features, such as high - efficiency conversion, multiple dimming options, and comprehensive protection features, are generally more expensive than basic models. The quality of components used in the driver also affects its cost; drivers with high - quality capacitors, resistors, and semiconductors tend to be more costly but offer better performance and reliability.

When choosing a driver, it is important to balance cost with performance and reliability. While a lower - cost driver may seem attractive, it may not provide the necessary features or reliability for the application, potentially leading to higher long - term costs due to frequent replacements or system failures. To get the best value for money, compare prices from different suppliers, consider purchasing in bulk for volume discounts, and negotiate with suppliers for better deals.

Availability and Lead Times

The availability of the LED driver and its lead times are critical factors, especially in time - sensitive projects. Driver shortages or long lead times can cause significant project delays and increase costs. To avoid these issues, work with reliable suppliers who can ensure a consistent supply of drivers and offer short lead times. Check the supplier's inventory levels, production capacity, and delivery schedules before placing an order.

It is also important to consider the availability of spare parts and technical support for the driver. In the event of a driver failure, having access to spare parts can minimize downtime and ensure the continued operation of the LED lighting system. Good technical support from the manufacturer or supplier can help resolve any issues quickly and efficiently, reducing the impact on the project.

Manufacturer and Brand Reputation

Research the Manufacturer

Before choosing an LED driver, research the reputation and track record of the manufacturer. Look for manufacturers with a proven history of producing high - quality, reliable products. Industry certifications, such as UL (Underwriters Laboratories), CE (Conformité Européene), or RoHS (Restriction of Hazardous Substances), are indicators that the driver meets certain safety and environmental standards. These certifications ensure that the driver has been tested and approved for use in specific regions or applications.

Reading customer reviews and testimonials can also provide valuable insights into the manufacturer's product quality, customer service, and technical support. Online forums, industry websites, and product review platforms are good sources of information. By researching the manufacturer, you can gain confidence in the quality and reliability of the LED driver and reduce the risk of purchasing a substandard product.

Brand Reputation

Brand reputation plays a significant role in the LED driver market. Well - known and respected brands are more likely to offer reliable products, good customer service, and technical support. Reputable brands often invest in research and development to improve their products' performance and features, ensuring that they meet the evolving needs of customers.

For example, brands like Philips, Cree, and Mean Well are widely recognized for their high - quality LED drivers. These brands offer a range of products with different features and specifications to suit various applications. On the other hand, choosing drivers from unknown or untested brands may pose a higher risk of failure and compatibility issues. While these drivers may be cheaper, the potential costs associated with product failures, replacements, and system downtime may outweigh the initial savings.

Testing and Validation

In - house Testing

Conducting in - house testing of the LED driver before installation is highly recommended to ensure its compatibility with the LEDs and the overall lighting system. Voltage and current measurements can verify that the driver is delivering the correct output levels and that the LEDs are operating within their specified ranges. Dimming functionality testing can check if the driver responds accurately to dimming commands and maintains consistent brightness and color quality.

Thermal testing is also important to assess the driver's heat - dissipation capabilities and ensure that it does not overheat during operation. Documenting the test results is essential for evaluating the driver's performance and reliability. Any discrepancies or issues identified during testing should be addressed before installing the driver in the actual application.

Field Testing

For large - scale or critical applications, field testing the LED driver in a real - world environment is advisable to assess its long - term performance and reliability. Design a field - testing plan that includes selecting representative test locations, monitoring the driver's performance over an extended period, and collecting data for analysis. This data can help identify any potential issues that may not have been apparent during in - house testing, such as the driver's performance under varying environmental conditions or long - term exposure to electrical fluctuations.

Based on the field - testing results, make any necessary adjustments or improvements to the driver or the lighting system. Field testing provides valuable insights into the driver's real - world performance and helps ensure that the LED lighting system will operate reliably and efficiently over its intended lifespan.

LED driver ICS Recommendations

When it comes to selecting LED driver integrated circuits (ICs), there are numerous factors to consider, such as application requirements, power efficiency, protection features, and dimming capabilities. To help you make an informed decision, here are some highly recommended LED driver ICs that stand out in the market for their performance and reliability.

1. LC5566LD https://www.sic-components.com/product/search?search=LC5566LD

Adopts DIP8 package and can be used for LED bulbs and downlights.

Has a built-in 650V power MOSFET and a startup circuit, and adopts a non-isolated flyback/boost-buck topology.

Supports analog dimming and has a built-in error amplifier (with an adjustable reference voltage).

The working modes are PWM (60kHz) and QR (quasi-resonant).

Protection functions: overcurrent protection (Pulse-by-pulse), overload protection (OLP, latched shutdown), overvoltage protection (OVP, latched shutdown), and thermal shutdown protection (TSD, latched shutdown).

Suitable for universal AC230V input, with an output power of 16W (at AC230V) and 20W (at AC230V).

Has a 650V startup circuit and supports single converter PFC (Power Factor Correction) operation.

2.LC101N https://www.sic-components.com/product/search?search=LC101N

Adopts DFN8 package. It is suitable for backlights in smart LED lighting applications, MR16 lamps, ceiling lights, streetlights, etc., and is especially suitable for single-channel control in LED backlight applications.

Has the function of LED string current balance.

Adopts a small package (DFN8), with a power dissipation PD of 1.3W.

No input and output capacitors are required, and the maximum differential voltage ΔVDIF is 350mV.

Protection functions: overcurrent protection (OCP), thermal shutdown protection (TSD, with an activation temperature of 130°C and no hysteresis).

The input voltage range is 2.4V - 35V, the output current range is 15mA - 150mA, the maximum output voltage is 35V, and the feedback voltage VFB is 200mV ± 3%.

3. LC5546LD https://www.sic-components.com/product/search?search=LC5546LD

The package, applicable lamps, power MOSFET, startup circuit, topological structure, operating mode, overcurrent protection, input voltage and output power are similar to those of LC5546AD.

The overload protection (OLP), overvoltage protection (OVP) and thermal shutdown protection (TSD) are in the latched shutdown mode.

By following the guidelines outlined in this article, you can make informed decisions that meet your specific application needs and expectations. Remember, a well - chosen LED driver is essential for the successful operation and performance of LED lighting systems, ensuring energy efficiency, longevity, and optimal lighting quality.

Hot Products

View MoreRelated Blogs

2000+

Daily average RFQ Volume

30,000,000

Standard Product Unit

2800+

Worldwide Manufacturers

15,000 m2

In-stock Warehouse

Wishlist (0 Items)

Wishlist (0 Items)