- RFQ

- BOM

-

Contact Us

Tel: +86-0755-83501315

Email: sales@sic-components.com

- Chinese

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

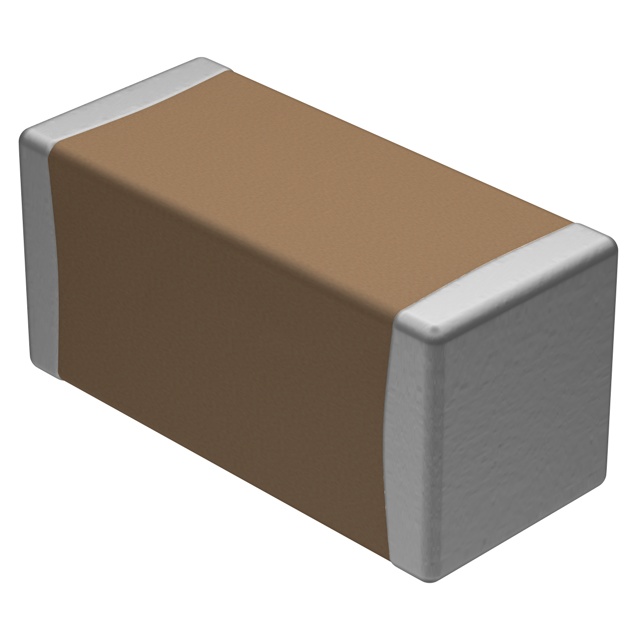

Ultra High Voltage Ceramic Capacitors

1. Introduction https://www.sic-components.com/ceramic-capacitors

Ultra high voltage ceramic capacitors are a specialized class of capacitors engineered to operate in high - voltage electrical systems. With the continuous advancement of high - voltage technologies in power transmission, medical equipment, and industrial applications, these capacitors have emerged as indispensable components. They are designed to handle voltages typically starting from 6000V and can go up to extremely high values, depending on the specific application requirements.

2. Working Principle

At their core, ultra high voltage ceramic capacitors operate on the same fundamental principle as regular capacitors. They consist of two conductive plates separated by a ceramic dielectric material. When a voltage is applied across the two plates, an electric field is established between them. This electric field causes the charges within the dielectric to align, creating an electric dipole moment.The ceramic materials used in these capacitors, often barium titanate - based compounds, have a high relative permittivity. For instance, pure barium titanate has a relative permittivity of around 5000. This high permittivity allows the capacitor to store a large amount of electrical charge. The relationship between capacitance (C), permittivity (ϵ), the area of the plates (A), and the distance between the plates (d) is given by the formula C=ϵA/d. In ultra high voltage ceramic capacitors, the choice of high - permittivity ceramic materials effectively increases the value of (ϵ), thereby enhancing the capacitance.

However, under high - voltage conditions, the behavior of the dielectric material changes. As the electric field strength within the dielectric increases, the dielectric constant gradually decreases. This phenomenon, known as voltage - dependent capacitance, is due to the saturation of the electric dipoles in the ceramic material. When the electric field becomes strong enough, all the dipoles are aligned, and the material's ability to respond to further increases in the electric field is reduced, leading to a decrease in capacitance.

3. Key Characteristics

3.1 High Voltage Withstand Capability

As the name implies, the most prominent feature of ultra high voltage ceramic capacitors is their ability to withstand extremely high voltages. They are designed to operate reliably in high - voltage environments without experiencing dielectric breakdown. Capacitors with working voltages ranging from 10kV to 150kV or even higher are available in the market, meeting the diverse needs of different high - voltage applications.

3.2 Capacitance Stability

Despite the voltage - dependent capacitance effect, efforts are made to ensure reasonable capacitance stability. Some ultra high voltage ceramic capacitors, especially those using paraelectric ceramic materials, exhibit relatively stable capacitance values over a certain range of voltages. This stability is crucial for applications where a consistent capacitance is required for the proper functioning of the circuit, such as in precision filtering and timing circuits.

3.3 Mechanical and Environmental Robustness

These capacitors often have a simple yet robust structure. The ceramic material provides good mechanical strength, allowing them to withstand mechanical vibrations and impacts that may occur in various operating environments. Additionally, they are resistant to many environmental factors. For example, they can be resistant to insulation liquids or activated gases, making them suitable for use in a wide range of industrial and outdoor applications.

3.4 Low Dissipation Factor

A low dissipation factor is another important characteristic. Dissipation factor represents the ratio of the energy dissipated in the capacitor to the energy stored in it. Ultra high voltage ceramic capacitors with low dissipation factors, such as some models from TDK's UHV and FHV series, are highly desirable as they minimize energy losses in the circuit. This is particularly important in high - voltage applications where even small energy losses can accumulate to significant amounts over time.

4. Application Scenarios

4.1 Power Systems

Power Transmission and Distribution: In power systems, ultra high voltage ceramic capacitors are used in multiple ways. They can be found in switches within distribution networks and circuit breakers in substations. Here, they play a vital role in improving the voltage distribution of high - voltage bushings. By ensuring a more uniform voltage distribution, they help to prevent premature aging and failure of other components in the high - voltage system.

Power Compensation and Filtering: They are also used for power compensation, current limiting, and filtering applications. In power factor correction circuits, these capacitors help to improve the efficiency of power transmission by reducing reactive power. In filtering applications, they can effectively remove high - frequency noise and harmonics from the power supply, ensuring a clean and stable power output for sensitive electrical equipment.

Metering and Energy Storage: Ultra high voltage ceramic capacitors are used in metering devices to accurately measure electrical parameters in high - voltage systems. Additionally, in certain energy storage applications within the power grid, such as for short - term energy buffering, these capacitors can store and release electrical energy as needed.

4.2 Medical Equipment

X - Ray Imaging Devices: In medical X - ray imaging devices like CT (Computed Tomography) machines and X - ray machines, ultra high voltage ceramic capacitors are essential. These devices require high - voltage power to generate X - rays. The capacitors are used in the high - voltage circuits to store and supply the necessary electrical energy for X - ray generation. Their ability to handle high voltages and provide stable capacitance is crucial for the accurate and consistent operation of these imaging devices, which are vital for medical diagnosis.

4.3 Industrial Equipment

Non - Destructive Testing (NDT) Equipment: In industrial non - destructive testing, such as for inspecting the integrity of materials and components without causing damage, high - voltage ceramic capacitors are used. They are part of the high - voltage power supplies in NDT equipment, enabling the generation of the necessary high - voltage pulses for techniques like ultrasonic testing, magnetic particle testing, and radiographic testing.

High - Power Laser Weapons and High - Voltage Electrostatic Precipitators: In high - power laser weapons, ultra high voltage ceramic capacitors are used for energy storage and pulse discharge. They store electrical energy and then release it in a high - voltage pulse to pump the laser medium, generating high - energy laser beams. In high - voltage electrostatic precipitators, which are used to remove dust and particulate matter from industrial exhaust gases, these capacitors are used to generate the high - voltage electric fields that attract and collect the charged particles.

5. Selection Considerations

5.1 Capacitance and Tolerance

Capacitance Value: The selection of the capacitance value depends entirely on the requirements of the specific circuit. For example, in a power factor correction circuit in a high - voltage power system, the capacitance value may need to be carefully calculated based on the reactive power requirements of the load. If the capacitance is too low, it may not effectively correct the power factor, while if it is too high, it can cause over - compensation and other issues.

Tolerance: Tolerance refers to the allowable deviation from the nominal capacitance value. For applications where a high degree of precision is not critical, such as in some low - frequency coupling and power supply filtering circuits, capacitors with a relatively high tolerance, such as ±5%, ±10%, or ±20% can be used. However, for circuits like oscillation circuits, delay circuits, and precision filters, capacitors with a very low tolerance, sometimes as low as ±1% or even less, are required to ensure accurate circuit performance.

5.2 Withstand Voltage

Voltage Rating: To ensure the safe and reliable operation of ultra high voltage ceramic capacitors, the selected capacitor's withstand voltage must be significantly higher than the actual working voltage in the circuit. A general rule of thumb is to choose a capacitor with a withstand voltage that is at least twice the maximum expected working voltage. This provides a safety margin to account for voltage surges, transients, and other electrical disturbances that may occur in the high - voltage system.

Derating: In addition to choosing the right voltage rating, derating the capacitor is also important. Derating means operating the capacitor at a voltage lower than its rated voltage to extend its lifespan and improve its reliability. For example, in a circuit with a maximum working voltage of 30kV, instead of using a capacitor with exactly a 30kV rating, a capacitor with a 60kV or higher rating may be selected and operated at the 30kV level.

5.3 Temperature Coefficient and High - Frequency Characteristics

Temperature Coefficient: The temperature coefficient of a capacitor describes how its capacitance changes with temperature. In applications where the capacitor is used in an environment with significant temperature variations, such as in industrial equipment operating in harsh outdoor conditions or in medical equipment where heat is generated during operation, a low - temperature - coefficient capacitor is preferred. For example, in an oscillating circuit in a high - voltage device that needs to maintain a stable frequency over a wide temperature range, a capacitor with a low - temperature coefficient will help ensure that the oscillation frequency remains stable.

High - Frequency Characteristics: In high - frequency circuits, the performance of the capacitor can be affected by factors such as inductance, lead inductance, and high - frequency loss. Ultra high voltage ceramic capacitors with good high - frequency characteristics, such as low equivalent series resistance (ESR) and low equivalent series inductance (ESL), should be selected. These capacitors are designed to minimize the negative impacts of these factors and maintain their capacitance and electrical performance at high frequencies.

6. Comparison of Products from Well - known Manufacturers

6.1 TDK

Product Features: TDK has over 40 years of experience in developing and selling ultra high voltage ceramic capacitors. Their UHV and FHV series use patented strontium titanate (SrTiO3) as the dielectric material. This results in capacitors with low dissipation and excellent voltage - capacitance characteristics. These capacitors are epoxy - encapsulated, making them suitable for high - voltage applications. The TS F, H, and GA series are designed for use in gas - insulated switchgear, while the FD series, molded from resins with outstanding insulation and moisture resistance, are ideal for high - voltage power circuits in electrical power transmission and receiving devices.Voltage and Capacitance Range: Their products typically cover a voltage range from 20kV to 50kV for certain material types (such as Z5T, Y5P, Y5S). For example, the highest - voltage - capacitance model currently offered is the FHV - 12AN 50kV 2100pF, Y5S material.

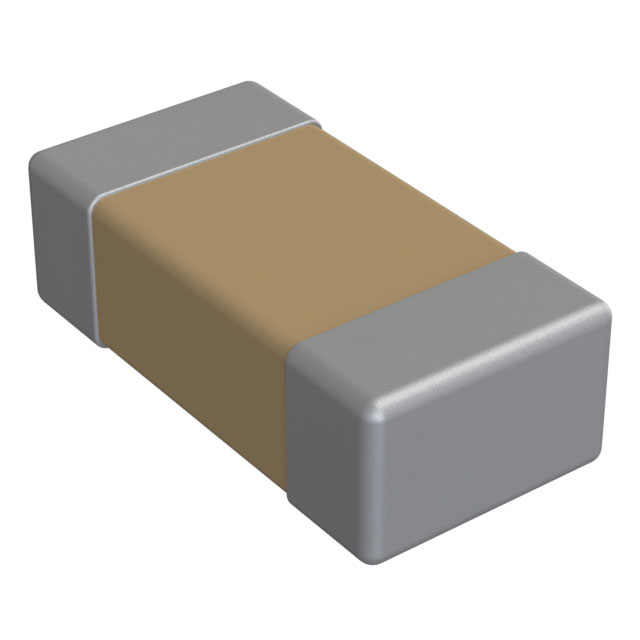

6.2 KYOCERA AVX

Product Features: KYOCERA AVX's high - voltage MLC capacitors are known for their high value, low leakage, and small size. They are designed to meet the performance requirements of applications such as snubbers in high - frequency power converters, resonators in switching power supplies (SMPS), and high - voltage coupling/DC blocking. These capacitors exhibit low ESRs at high frequencies, making them suitable for high - frequency, high - voltage applications.

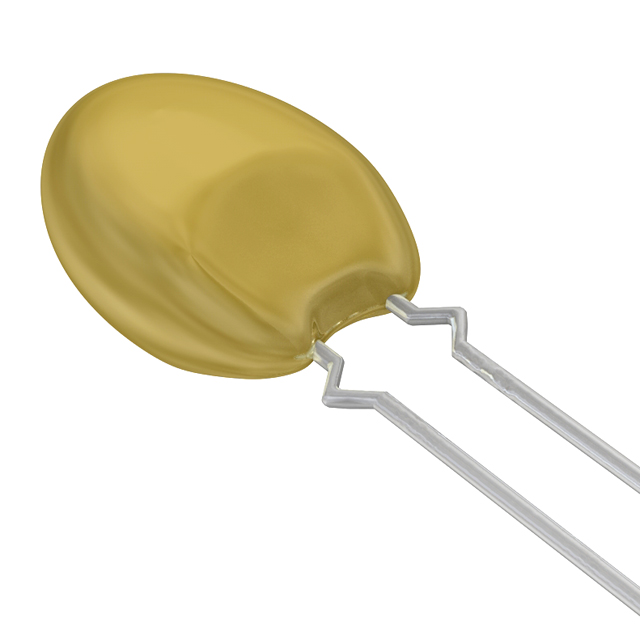

6.3 HVC Capacitor

Product Features: HVC Capacitor, a Chinese manufacturer, offers an alternative to well - known international brands. Their door - knob - type high - voltage ceramic capacitors cover a wide voltage range from 10kV to 150kV, with main materials such as N4700, Y5U, Y5T, etc. They use an innovative internal dual - chip series or parallel structure. This allows them to produce capacitor specifications with higher voltage and larger capacitance compared to some traditional designs. For example, they can offer products like 50kV 8000pF N4700, 60kV 2000pF N4700, and 150kV 1000pF N4700. The copper - coated electrodes on their ceramic chips provide better high - voltage and high - current resistance capabilities compared to traditional silver - plated electrodes.

Ultra high voltage ceramic capacitors are critical components in modern high - voltage electrical systems. Their unique working principle, key characteristics, and wide range of applications make them essential for the proper functioning of power systems, medical equipment, and industrial devices. When selecting these capacitors, careful consideration of various factors is necessary, and comparing products from different manufacturers can help in making the most suitable choice for a given application.

https://www.sic-components.com/ceramic-capacitors

Hot Products

View MoreRelated Blogs

2000+

Daily average RFQ Volume

30,000,000

Standard Product Unit

2800+

Worldwide Manufacturers

15,000 m2

In-stock Warehouse

Wishlist (0 Items)

Wishlist (0 Items)