- RFQ

- BOM

-

Contact Us

Tel: +86-0755-83501315

Email: sales@sic-components.com

- Chinese

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

What is a Zero Drift Amplifier?

In the realm of precision analog electronics, maintaining accuracy over time and environmental changes is paramount. Traditional operational amplifiers (op-amps) often suffer from performance degradation due to drift—slow, unintended changes in output voltage caused by temperature variations, aging, or power supply fluctuations. To address this challenge, zero drift amplifiers (also known as auto-zero or chopper-stabilized amplifiers) have emerged as a critical solution, offering exceptional stability and precision for demanding applications. This article explores zero drift amplifiers in detail, covering their working principles, key characteristics, advantages, limitations, and practical applications.

Defining Zero Drift Amplifiers

A zero drift amplifier is a specialized type of operational amplifier designed to minimize offset voltage drift and gain drift—two primary sources of error in precision circuits. Offset voltage drift refers to the slow change in an amplifier’s input offset voltage (Vos) over time or temperature, while gain drift describes the variation in gain with environmental conditions.

Unlike conventional op-amps, which may exhibit drift values of 1–10 µV/°C, zero drift amplifiers achieve drift specifications as low as 0.01 µV/°C, making them ideal for applications requiring long-term accuracy, such as sensor interfaces, medical devices, and precision measurement systems.

How Zero Drift Amplifiers Work: Core Principles

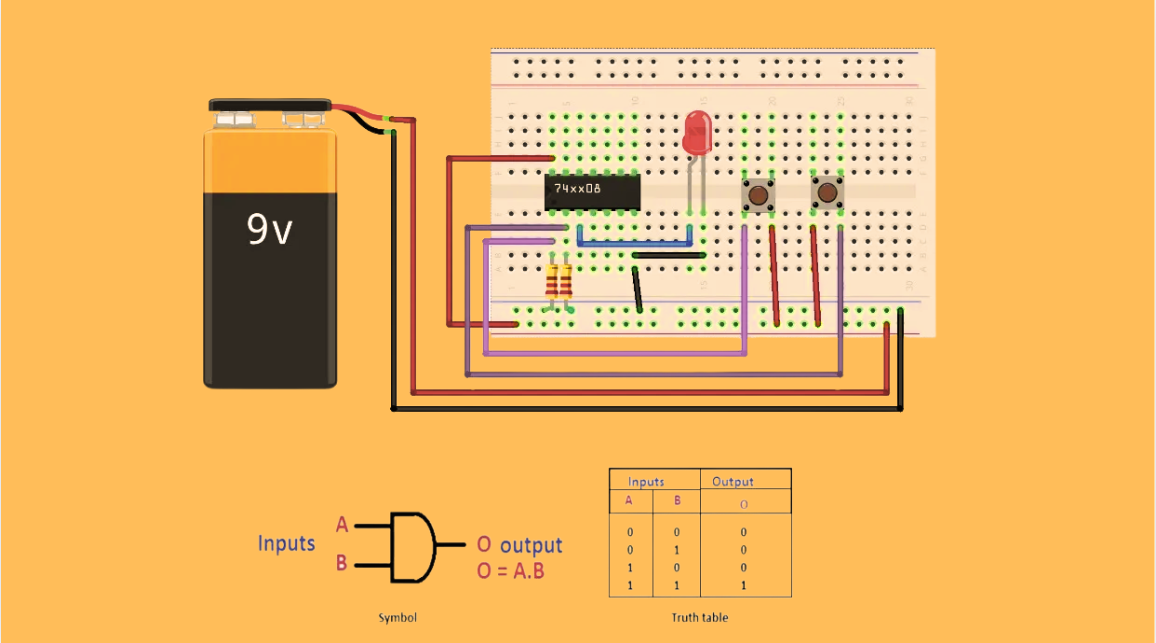

Zero drift amplifiers eliminate drift through active compensation techniques. The two most common approaches are chopper stabilization and auto-zeroing, though modern designs often combine elements of both.

1. Chopper Stabilization

Chopper stabilization uses a high-frequency switching (chopping) mechanism to "modulate" the input signal, separate it from drift-related errors, and then "demodulate" it to recover a clean output. Here’s a step-by-step breakdown:

Modulation: The input signal is rapidly switched (chopped) at a high frequency (typically 10–100 kHz) using MOSFET switches. This converts the DC or low-frequency input signal into an AC signal centered at the chopping frequency.

Amplification: The AC signal is amplified by a high-gain, but potentially drifty, main amplifier. Since drift and offset errors are DC or low-frequency, they remain unmodulated.

Demodulation: The amplified AC signal is "chopped" again (demodulated) using a synchronized switch, converting it back to a DC signal. Drift and offset errors, which were not modulated, are rejected during this process.

Filtering: A low-pass filter removes residual chopping frequency components, leaving a clean output signal with minimal drift.

This technique effectively separates the desired signal from drift-related errors, as drift is not affected by the high-frequency chopping.

2. Auto-Zeroing

Auto-zeroing amplifiers periodically calibrate themselves to cancel offset and drift. The process occurs in two phases:

Signal Phase: The amplifier operates normally, amplifying the input signal. During this phase, a capacitor stores the offset voltage of the main amplifier.

Calibration Phase: The input is disconnected, and the amplifier’s input is shorted (or connected to a reference). The amplifier measures its own offset voltage, stores this value in a capacitor, and subtracts it from the output during the next signal phase.

This calibration repeats at a high frequency (e.g., 1 kHz to 100 kHz), continuously canceling offset and drift. Unlike chopper stabilization, auto-zeroing introduces minimal noise at the chopping frequency but may cause small glitches during calibration.

3. Hybrid Designs

Modern zero drift amplifiers often combine chopper stabilization and auto-zeroing to optimize performance. For example, a chopper-stabilized front end handles low-frequency signals and drift, while auto-zeroing corrects residual errors, achieving ultra-low drift and low noise.

Key Characteristics of Zero Drift Amplifiers

1. Ultra-Low Offset Voltage and Drift

Offset Voltage (Vos): Typically 1 µV or lower (compared to 10–100 µV for conventional op-amps).

Offset Drift: As low as 0.01 µV/°C, ensuring minimal error over temperature ranges from -40°C to 125°C.

2. Low Noise Performance

While chopper-stabilized amplifiers introduce small amounts of switching noise (at the chopping frequency), modern designs minimize this with advanced filtering. Auto-zeroing amplifiers may exhibit 1/f noise (flicker noise) at very low frequencies, but this is often negligible for most applications.

3. High Common-Mode Rejection Ratio (CMRR)

Zero drift amplifiers achieve high CMRR (typically 120 dB or higher), rejecting noise from common-mode signals (e.g., power supply fluctuations or electromagnetic interference).

4. Wide Supply Voltage Range

They operate over a broad range of supply voltages, from 1.8V (for portable devices) to 36V (for industrial systems), making them versatile for diverse applications.

5. Bandwidth Limitations

Zero drift amplifiers are optimized for low-frequency signals (DC to tens of kHz). Their bandwidth is limited by the chopping or auto-zeroing frequency, as higher frequencies may alias with the switching signal.

Advantages of Zero Drift Amplifiers

Unmatched Precision: Eliminates drift-related errors, ensuring long-term accuracy in critical applications.

Temperature Stability: Performs reliably across extreme temperature ranges, making them suitable for industrial and automotive environments.

Simplified Calibration: Reduces or eliminates the need for manual trimming or calibration in production, lowering manufacturing costs.

Robustness to Aging: Minimizes performance degradation over time, extending the lifespan of precision systems.

Compatibility with Low-Level Signals: Ideal for amplifying weak signals from sensors (e.g., thermistors, strain gauges, or pressure transducers) where even small drift would corrupt data.

Limitations and Considerations

Limited Bandwidth: Not suitable for high-frequency signals (above 100 kHz) due to chopping/auto-zeroing artifacts.

Switching Noise: Chopper-stabilized amplifiers generate noise at the chopping frequency, which may require additional filtering in sensitive applications (e.g., audio).

Power Consumption: Higher than conventional op-amps due to the active compensation circuitry, though low-power variants (e.g., <1 mW) are available for battery-powered devices.

Cost: More expensive than standard op-amps, making them impractical for non-precision applications.

Applications of Zero Drift Amplifiers

Zero drift amplifiers excel in scenarios where precision and stability are critical. Key applications include:

1. Sensor Interfaces

Strain Gauges: Measure 微小的 resistance changes in structural materials, requiring ultra-low drift to detect minute forces.

Thermocouples and RTDs: Amplify small temperature-dependent voltages (µV-level) without drift-induced errors.

Pressure Sensors: Ensure accurate measurement of low-pressure differentials in medical or industrial systems.

2. Medical Devices

ECG/EKG Machines: Amplify weak cardiac signals (mV-level) over long monitoring periods without drift corrupting data.

Blood Glucose Monitors: Precisely measure tiny currents from chemical reactions, where drift would lead to inaccurate readings.

Infusion Pumps: Maintain precise flow rates through stable control loops, critical for patient safety.

3. Precision Measurement Systems

Digital Multimeters (DMMs): Achieve high accuracy in DC voltage/current measurements, even over extended use.

Calibration Equipment: Provide stable reference signals for calibrating other instruments.

Data Acquisition Systems: Ensure low-error conversion of analog signals to digital for scientific or industrial monitoring.

4. Industrial Automation

Process Control: Maintain stable feedback loops in chemical, pharmaceutical, or manufacturing processes, where drift could cause costly errors.

Load Cells: Measure weight or force with high precision in scales or material handling systems.

5. Energy and Power Systems

Battery Management Systems: Monitor cell voltages in energy storage systems with minimal drift, ensuring safe and efficient operation.

Power Meters: Measure small power losses in electrical grids, where accuracy directly impacts efficiency calculations.

Popular Zero Drift Amplifier Models

Leading manufacturers offer a range of zero drift amplifiers tailored to specific applications:

Texas Instruments OPA388: A low-power chopper-stabilized op-amp with 0.02 µV/°C drift, ideal for portable sensors.

https://www.sic-components.com/product/search?search=OPA388

Analog Devices AD8551: An auto-zeroing op-amp with 0.005 µV/°C drift and high CMRR, suitable for precision instrumentation.

https://www.sic-components.com/product/search?search=+AD8551

Microchip MCP6V0x: Low-voltage zero drift amplifiers (1.8V to 5.5V) with 1 µV offset, designed for battery-powered devices.

https://www.sic-components.com/product/search?search=MCP6V0x

Maxim MAX9632: A high-speed (1 MHz) zero drift op-amp, balancing precision and bandwidth for mid-frequency applications.

https://www.sic-components.com/product/search?search=MAX9632

Conclusion

Zero drift amplifiers represent a significant advancement in analog circuit design, addressing the critical challenge of drift in precision systems. By leveraging chopper stabilization, auto-zeroing, or hybrid techniques, they achieve unparalleled stability, making them indispensable for applications where accuracy cannot be compromised. While they have limitations in bandwidth and cost, their benefits far outweigh these drawbacks in scenarios requiring long-term precision—from medical diagnostics to industrial process control. As technology advances, zero drift amplifiers will continue to evolve, enabling even more precise and reliable electronic systems.

https://www.sic-components.com/amplifierscategory-1

Hot Products

View MoreRelated Blogs

2000+

Daily average RFQ Volume

30,000,000

Standard Product Unit

2800+

Worldwide Manufacturers

15,000 m2

In-stock Warehouse

Wishlist (0 Items)

Wishlist (0 Items)