- RFQ

- BOM

-

Contact Us

Tel: +86-0755-83501315

Email: sales@sic-components.com

- Chinese

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

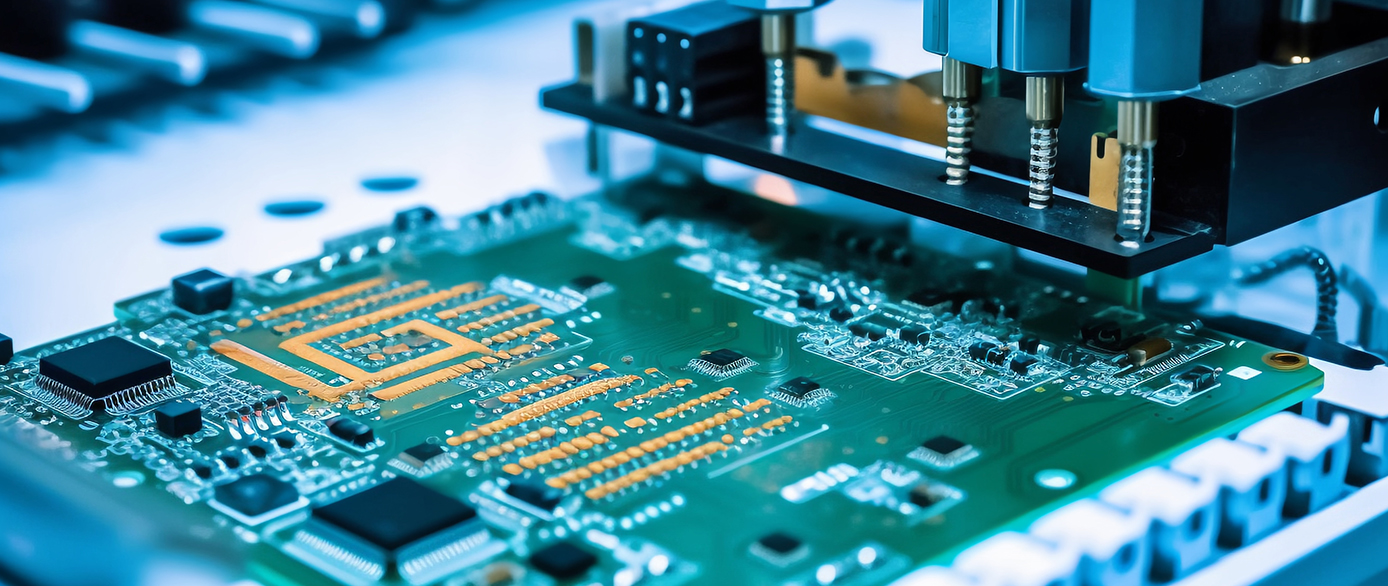

Digital Chip

In the rapid development of modern electronic technology, integrated circuits (ICs) play a crucial role and have become the core components of electronic devices. ICs are the general term for transistor - based products. According to their functions, they can be carefully classified into digital ICs, analog ICs, microwave ICs, and many other types. Among them, digital integrated circuits, with their excellent performance and wide range of applications, have shown a rapid development trend in recent years and have become one of the most widely used and fastest - growing varieties in the integrated circuit family. Whether it is the smartphones and computers we use in our daily lives, or the advanced artificial intelligence devices and cloud computing servers, they all rely on the support of digital chips. Therefore, a deep exploration of the relevant characteristics, applications, and development trends of digital chips is of great significance for understanding the development context of modern electronic technology. Next, this article will conduct a detailed analysis of digital chips.

Development History of Digital Chips

The development history of digital chips is a process of continuous innovation and development, which can be traced back to the mid-20th century.

Pre-chip Era - The Invention of Transistors: Before the emergence of integrated circuits, electronic devices relied on vacuum tubes, which were large in size, low in efficiency, high in power consumption, and generated excessive heat. In 1947, John Bardeen, Walter Brattain, and William Shockley at Bell Labs invented the transistor. Transistors were smaller, more efficient, and more reliable than vacuum tubes, laying the foundation for the miniaturization of electronic devices and paving the way for the development of digital chips.

The Birth of Integrated Circuits - The First Digital Chip: In the early 1950s, the concept of integrating multiple transistors and electronic components onto a single piece of semiconductor material was put forward. In 1958, Jack Kilby of Texas Instruments demonstrated a working integrated circuit, which consisted of a transistor, a capacitor, and a resistor on a piece of germanium. In 1960, Robert Noyce of Fairchild Semiconductor improved Kilby's design by using silicon, which had better performance and became the standard material for integrated circuits. Kilby and Noyce are regarded as the co-inventors of integrated circuits. Their inventions marked the birth of digital chips and opened the door to the era of integrated circuits.

The Development of Digital Chips - From Small-Scale Integration to Ultra-Large-Scale Integration: In the early 1960s, small-scale integration (SSI) and medium-scale integration (MSI) circuits came into being. These circuits contained several to hundreds of transistors and were applied in calculators, military equipment, and early computers. In 1968, the Radio Corporation of America (RCA) launched the first commercially available digital integrated circuit based on complementary metal-oxide-semiconductor (CMOS) technology, the 4000 series. In 1970, Intel introduced the 1103 chip using a 10-micron pMOS process. It was a 1K-bit dynamic random-access memory (DRAM), marking the emergence of large-scale integration (LSI) circuits. In 1971, Intel launched the world's first microprocessor, the 4004, which integrated 2,300 transistors. In 1980, very-large-scale integration (VLSI) circuits with more than 10,000 transistors per chip were born. In 1989, the era of ultra-large-scale integration (ULSI) with more than 1 million transistors per chip arrived. In 2005, the scale of digital integrated circuits exceeded 1 billion components, entering the era of large-scale system-on-chip (SoC) products.

Modern Digital Chip Technology - System-on-Chip and Multi-core Processors: In the 21st century, driven by the rise of nanotechnology, digital chip technology has made remarkable progress. The size of transistors in modern chips is measured in nanometers, achieving unprecedented levels of integration and performance. Digital chips have evolved into complex systems, namely system-on-chip (SoC), which integrates all the components of a computer or electronic system, including the central processing unit (CPU), graphics processing unit (GPU), memory, and peripheral devices, onto a single chip. This integration improves performance, reduces power consumption, and minimizes the physical size of devices. In addition, the development of multi-core processors, that is, integrating multiple processing units on a single chip, has greatly enhanced computing power and efficiency.

Today, digital chips are widely used in various fields such as computers, communications, consumer electronics, automotive electronics, industrial control, and artificial intelligence, playing a crucial role in promoting the development of modern technology.

Definition and Function of Digital Chips

Digital integrated circuits, in short, are ICs specifically designed to transmit, process, and manipulate digital signals. The so - called digital signals are essentially composed of a series of discrete binary values (0 and 1), which are transmitted and processed in the form of pulse square waves. Digital chips are like the "brains" of electronic devices, undertaking various complex calculation, logical judgment, and data processing tasks.

Taking the CPU (Central Processing Unit) as an example, it is the core component of a computer system. It can quickly execute various instructions, perform arithmetic and logical operations, and coordinate and control various components of the computer. During the operation of the computer, the CPU reads instructions and data from the memory, and after being processed by the digital chip, outputs the results to the corresponding devices. Another example is the logic circuit, which is an important part of the digital chip. By performing logical operations (such as AND, OR, NOT, etc.) on the input digital signals, it realizes various logical functions, providing a solid foundation for the normal operation of electronic devices.

In modern electronic devices, digital chips are widely used. In the communication field, digital chips are widely used in mobile phones, routers, and other devices to realize the encoding, decoding, modulation, and demodulation of signals, ensuring the high - speed and stable transmission of data. In the consumer electronics field, digital chips enable smart watches, smart home devices, and others to achieve various intelligent functions, bringing great convenience to people's lives. In the industrial control field, digital chips are used to achieve precise control and monitoring of the production process, improving production efficiency and product quality.

Classification of Digital Chips

Digital integrated circuits (ICs) can be primarily classified into the following categories:

Combinational Logic ICs: These ICs consist of interconnected logic gates and perform functions based solely on the current input values. Examples include adders, multiplexers, demultiplexers, encoders, and decoders.

Sequential Logic ICs: Sequential logic ICs incorporate memory elements and store information based on both the current input values and the stored previous states. Flip-flops, registers, counters, shift registers, and memory units such as RAM and ROM are examples of sequential logic ICs.

Microprocessors and Microcontrollers: These are highly complex digital ICs that contain a central processing unit (CPU), memory, input/output interfaces, and other functional units. Microprocessors are general-purpose devices capable of executing a wide range of instructions, while microcontrollers are typically used for specific applications and have integrated peripherals such as timers, UARTs, and ADCs.

Programmable Logic Devices (PLDs): PLDs are digital ICs that can be programmed or configured by the user to implement specific logic functions or circuits. Examples include programmable logic arrays (PLAs), programmable array logic (PAL), complex programmable logic devices (CPLDs), and field-programmable gate arrays (FPGAs).

Memory ICs: Memory ICs are used for storing and retrieving digital data. They include various types of memory such as random access memory (RAM), read-only memory (ROM), electrically erasable programmable read-only memory (EEPROM), flash memory, and cache memory.

Communication ICs: These ICs are designed for digital communication systems and include serializers/deserializers (SERDES), network interface controllers (NICs), Ethernet switches, modems, and codecs.

Interface ICs: Interface ICs facilitate the connection and communication between different components or systems. They include USB controllers, I2C (Inter-Integrated Circuit) interfaces, SPI (Serial Peripheral Interface) controllers, HDMI (High-Definition Multimedia Interface) controllers, and UARTs (Universal Asynchronous Receiver-Transmitters).

Clock and Timing ICs: These ICs generate and distribute clock signals to synchronize the operation of digital systems. They include crystal oscillators, phase-locked loops (PLLs), clock dividers, timers, and frequency synthesizers.

Differences between Digital Chips and Analog Chips

(1) Signal Processing Methods

Digital chips and analog chips have essential differences in signal processing methods. Digital chips process discontinuous signals, which exist in the form of pulse square waves, and their values have only two states: 0 and 1. Digital chips realize various functions by performing logical operations and processing on these discrete digital signals. In contrast, analog chips process continuous natural analog signals, such as sound, image, temperature, pressure, and other signals. The values of these signals can change continuously within a certain range and can usually be converted into sine waves for research. Analog chips realize signal transmission and processing by amplifying, filtering, modulating, and other processing of analog signals.

(2) Lifecycle

The design concept of digital ICs mainly focuses on the ratio of operation speed to cost. In order to gain an advantage in market competition and achieve higher operation speed and lower cost, designers of digital chips will constantly adopt more efficient algorithms and new manufacturing processes. This continuous pursuit of innovation and optimization leads to a relatively short lifecycle of digital ICs, which is about 1 - 2 years. With the continuous progress of technology, new digital chips are emerging continuously, and the old chips will soon be phased out.

In contrast, analog ICs pay more attention to characteristics such as high signal - to - noise ratio, low distortion, low power consumption, high reliability, and stability. Once the analog chip product reaches the design goal, its performance and quality can remain relatively stable, and it has a long lifecycle. For example, the audio operational amplifier NE5532 has become one of the most commonly used audio - amplifying ICs since its introduction in the late 1970s, thanks to its excellent sound quality and stability. To this day, nearly 50% of multimedia speakers still use NE5532, and its service life has exceeded 25 years. Due to the long lifecycle of analog ICs, their supply in the market is relatively stable, and the price is usually low.

(3) Manufacturing Process

In terms of the manufacturing process, digital integrated circuits mostly adopt the CMOS (Complementary Metal - Oxide - Semiconductor) process. The CMOS process has the advantages of low power consumption, high integration, and low cost. It is very suitable for working in a low - voltage environment and can meet the requirements of digital chips for cost and integration. With the continuous development and progress of the CMOS process, the performance and integration of digital chips have been greatly improved.

However, due to their own characteristics, analog ICs rarely use the CMOS process. Analog ICs usually need to output high voltage or high current to drive other components, while the driving ability of the CMOS process is relatively poor. In addition, the key performance indicators of analog ICs, such as low distortion and high signal - to - noise ratio, are relatively easier to achieve in a high - voltage environment. Therefore, analog ICs mainly used the bipolar process in the early days, but the bipolar process has the problem of high power consumption. In order to overcome the shortcomings of the bipolar process, the BiCMOS process emerged later. It combines the advantages of the bipolar process and the CMOS process, which can provide higher driving ability and reduce power consumption. In addition, there are also the CD process (combining the CMOS process with the DMOS process) and the BCD process (combining the advantages of bipolar, CMOS, and DMOS processes). In the high - frequency field, there are also special processes such as SiGe (Silicon - Germanium) and GaAS (Gallium Arsenide). The application of these special processes requires the close cooperation of wafer foundries and the in - depth understanding and mastery of the process by designers, while digital IC designers basically do not need to consider the process issues too much.

(4) Relationship with Components

In the design process of digital chips, factors such as noise and distortion generated by components are basically not considered. Since digital signals have only two states, 0 and 1, the requirement for signal accuracy is relatively low. Therefore, digital chips also have relatively low requirements for the accuracy and stability of components. At the same time, digital chips do not need to pay special attention to the symmetrical structure and parameter matching of component layout, because the logical function of digital circuits is mainly realized by the internal logical circuits of the chip, and the layout and parameters of components have little impact on its performance.

In contrast, the design of analog ICs needs to fully consider various characteristics of components in the entire linear working area, such as current amplification characteristics, small - current characteristics, and frequency characteristics. In order to ensure the performance of analog ICs, designers usually need to consider the symmetrical structure and parameter matching form of component layout to reduce the mutual interference and error between components. In addition, analog ICs must also have low - noise and low - distortion performance, because components such as resistors, capacitors, and inductors will generate noise or distortion during operation, and these noises and distortions will directly affect the performance of analog ICs. Therefore, analog IC designers must be familiar with almost all electronic components, understand their performance and characteristics, so as to make reasonable choices and layouts in the design process.

(5) Design and Testing

Digital chip design has more EDA (Electronic Design Automation) - assisted tools. These tools can help designers quickly carry out circuit design, simulation, and verification. By using EDA tools, designers can simulate and optimize the circuit of digital chips on the computer, greatly improving the design efficiency and accuracy. At the same time, the design of digital chips is relatively standardized and standardized, and there is a set of mature design processes and methods, which makes the design of digital chips easier to master and implement.

In contrast, there are relatively fewer design - assisted tools for analog ICs, and the number of EDA tools that can be used is much less than that for digital IC design. The design of analog ICs requires designers to have comprehensive knowledge and long - term experience. They not only need to be familiar with the manufacturing technology and process of ICs and wafers, but also need to understand the electrical and physical characteristics of most components. Usually, few designers can have the knowledge and experience in these aspects at the same time. In terms of experience, analog IC designers need at least 3 - 5 years of practical experience, and excellent analog IC designers need 10 years or more of experience accumulation.

In addition, due to the large power consumption of analog ICs, the involvement of many factors, and the need to maintain high stability, its certification cycle is long. The testing cycle of analog ICs is also relatively long and complex. It is necessary to comprehensively test and verify various performance indicators of analog ICs to ensure that their performance meets the design requirements. Some analog IC products also need to adopt special processes and packaging and must be jointly developed with wafer factories, such as the BCD process and the 30V high - voltage process. In addition, some products also need WCPS wafer - level packaging, which further increases the difficulty and cost of analog IC design and testing.

Digital Chip Applications

Computer Field

CPU: As the core component of a computer, the digital chip realizes functions such as data processing, arithmetic operations, and instruction execution. Examples include Intel Core series processors and AMD Ryzen series processors. They continuously enhance computing power and performance, driving the development of computer technology.

Memory Chips: These include Random Access Memory (RAM) and Read-Only Memory (ROM), which are used to store the programs and data when the computer is running. For instance, the DDR (Double Data Rate) series of memory chips continuously improve data transfer speed and storage capacity to meet the computer's demand for high-speed data processing.

Communication Field

Baseband Chips: They are one of the core chips in communication devices such as mobile phones and are used to process digital signals to achieve communication functions such as voice and data. For example, the Qualcomm Snapdragon series of baseband chips and the baseband part in Huawei Kirin series chips support different communication standards and frequency bands, providing high-speed and stable communication connections.

Optical Communication Chips: In fiber optic communication, digital chips are used to realize the conversion between optical signals and electrical signals, as well as data encoding and decoding. For example, the digital signal processing chips in optical modules improve the transmission rate and distance of optical communication.

Consumer Electronics Field

Digital TV Chips: They are responsible for functions such as the decoding of TV signals, and the processing of images and sounds. For example, MediaTek's TV chips support multiple video formats and high-definition resolutions, providing an excellent audio-visual experience.

Audio Processing Chips: These are used in audio devices such as headphones and speakers to realize the digital processing, decoding, and amplification of audio signals. For example, the audio decoding chips of ESS Company are favored by many audio device manufacturers due to their high-fidelity audio processing capabilities.

Automotive Electronics Field

Engine Control Unit (ECU): Digital chips in the ECU are used to monitor and control the running status of the engine. For example, Bosch's ECU chips, by processing the data from various sensors, precisely control parameters such as fuel injection and ignition timing, improving the engine's performance and fuel economy.

Autonomous Driving Chips: With the development of autonomous driving technology, digital chips undertake the important task of processing data from sensors such as cameras and radars. For example, NVIDIA's DRIVE series of chips have powerful computing capabilities and can process a large amount of image and sensor data in real-time, realizing autonomous driving functions such as environmental perception and decision-making planning.

Industrial Control Field

Programmable Logic Controller (PLC): Digital chips are the core components of PLCs and are used to realize functions such as logical operations, sequential control, timing, and counting. They are widely applied in industrial automation production lines, machine tool control, and other fields. For example, Siemens' S7 series of PLCs achieve precise control of industrial equipment through programming.

Industrial Sensor Chips: In industrial production, digital chips are used in sensors to realize the conversion, amplification, and processing of signals. For example, STMicroelectronics' pressure sensor chips and temperature sensor chips provide accurate sensor data for industrial control systems.

Development Trends of Digital Chips

With the continuous development of digital technology, digital chips show the following important development directions in terms of speed, integration, and power consumption.

In terms of speed, as the requirements of electronic devices for processing power are getting higher and higher, the operating speed of digital chips will continue to increase. In order to achieve higher speed, chip manufacturers will continuously improve the manufacturing process, reduce the size of transistors, and increase the clock frequency of chips. At the same time, new architectures and algorithms will also emerge continuously to optimize the performance of digital chips and improve the speed and efficiency of data processing.

In terms of integration, digital chips will develop towards higher integration. By integrating more functional modules into one chip, the volume of the chip can be reduced, the cost can be reduced, and the reliability and performance of the system can be improved. In the future, digital chips may integrate more processor cores, memories, sensors, and other components to achieve more complex functions.

In terms of power consumption, with the rapid development of mobile devices and the Internet of Things, the requirements for the power consumption of digital chips are also getting higher and higher. In order to meet the low - power - consumption requirements, chip manufacturers will continuously research and develop new technologies and processes to reduce the power consumption of chips. For example, adopting more advanced CMOS processes, optimizing circuit design, and adopting low - power - consumption architectures and algorithms can effectively reduce the power consumption of digital chips.

In addition, the integration trend of digital chips and analog technology is becoming increasingly obvious. In many application scenarios, digital chips and analog chips need to work together to achieve more powerful functions. For example, in smartphones, digital chips are responsible for processing data and running applications, while analog chips are responsible for processing analog signals such as audio and video. In the future, with the continuous development of digital technology and analog technology, the integration of the two will be closer, and there may be more mixed - signal chips. These chips will have both digital processing and analog processing capabilities, bringing new opportunities and challenges to the development of electronic devices.

This integration will have a profound impact on the performance and function of electronic devices. On the one hand, the integration of digital chips and analog technology can improve the performance of electronic devices, such as improving the accuracy and speed of signal processing and enhancing the intelligence of devices. On the other hand, the integration can also expand the functions of electronic devices, such as achieving more powerful multimedia processing capabilities and more accurate sensor data processing.

SIC Electronics Limited is a global distributor of high-quality electronic components, with a particular focus on Digital Chips. We have always adhered to the service tenets of strict quality control, rapid response to customer needs, and provision of 100% high-quality products, especially when it comes to Digital Chips.

In order to better serve customers worldwide and provide more favorable and convenient delivery services for Digital Chips, SIC Electronics has established numerous offices globally. By fully leveraging the advantages of each region and combining our own inventory of Digital Chips with market dynamics, we are able to promptly respond to customer needs and provide efficient and high-quality services related to these chips.

Currently, our Digital Chip products and the business related to them cover industries such as military, automotive, medical, consumer electronics, industrial control, the Internet of Things, new energy, and communication. Whether it's the latest microprocessors for high-performance computing in the military and automotive sectors, or specialized memory chips for medical devices and consumer electronics, we have a wide range of Digital Chip offerings.

We not only provide products and services to customers but also carry out relevant peripheral cooperation in the Digital Chip domain. If you have Digital Chip products to sell or encounter any product-related issues, such as compatibility problems or performance optimization needs, you are welcome to contact us at any time.

In addition, we have our own warehouses specifically dedicated to storing Digital Chips, top-notch quality control personnel who rigorously inspect each chip to ensure its performance and reliability, a senior procurement team that sources the best Digital Chips from around the world, numerous deeply cooperative factories that can customize chips according to specific requirements, and global trade logistics partners that ensure the timely and safe delivery of our Digital Chip products. We are delighted to share resources with our customers and look forward to achieving win-win cooperation in the dynamic and ever-evolving field of Digital Chips.

https://www.sic-components.com/integrated-circuits-ics

Hot Products

View MoreRelated Blogs

2000+

Daily average RFQ Volume

30,000,000

Standard Product Unit

2800+

Worldwide Manufacturers

15,000 m2

In-stock Warehouse

Wishlist (0 Items)

Wishlist (0 Items)