- RFQ

- BOM

-

Contact Us

Tel: +86-0755-83501315

Email: sales@sic-components.com

- Chinese

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

What is an LED driver IC?

In the rapidly evolving world of lighting technology, LED (Light - Emitting Diode) lighting has emerged as a dominant force due to its energy - efficiency, long lifespan, and environmental friendliness. Central to the proper functioning of LED lighting systems is the LED driver IC. This article aims to offer a comprehensive exploration of LED driver ICs, covering their definition, working principles, types, features, and applications.

LED driver IC Definition and Basic Concept

An LED driver IC is a specialized integrated circuit meticulously designed to regulate the electrical power supplied to light - emitting diodes. Acting as the control center for LED operation, it manages critical parameters such as current, voltage, and power. Just as a conductor orchestrates an orchestra, an LED driver IC coordinates the flow of electricity to ensure that LEDs perform at their best.

LEDs have specific electrical requirements. They are current - driven devices, meaning their performance is highly dependent on a consistent and appropriate flow of electric current. Without a proper LED driver IC, LEDs are at risk of damage. Excessive current can cause overheating, which not only reduces the lifespan of the LED but also leads to a decline in light output quality. Insufficient current, on the other hand, may result in dim or inconsistent illumination. By precisely regulating the power supply, LED driver ICs enable LEDs to operate at their optimal performance levels. This not only ensures stable illumination but also maximizes energy efficiency, making LED lighting systems more cost - effective and sustainable.

LED driver IC Working Principles

Power Conversion Basics

One of the primary functions of an LED driver IC is power conversion. When the input power is alternating current (AC), typically from the mains supply, the LED driver IC performs AC - to - DC conversion. This process involves rectifying the AC waveform into a unidirectional direct current (DC) that is suitable for powering LEDs. In applications where both the input and output are DC, such as in battery - powered LED devices, the LED driver IC may perform DC - to - DC conversion. This can involve stepping up or stepping down the voltage as per the requirements of the LED circuit, ensuring that the power is delivered in the most efficient manner.

Current and Voltage Regulation

Current regulation is of utmost importance in LED operation, and LED driver ICs are designed to maintain a constant current flow through the LEDs. Since LEDs are highly sensitive to current variations, even minor fluctuations can significantly impact their brightness and lifespan. LED driver ICs use sophisticated control mechanisms to monitor and adjust the current, ensuring that it remains within the optimal range for the specific LEDs being used.

Voltage regulation is also crucial, especially when dealing with different LED configurations. LEDs can be connected in series, parallel, or in a combination of both. In a series connection, the voltage across each LED adds up, while in a parallel connection, the voltage remains the same across all LEDs. The LED driver IC must be able to supply the appropriate voltage to each LED or LED string, taking into account the total resistance and the number of LEDs in the circuit. This ensures that all LEDs receive the correct amount of power and operate uniformly.

Control Signals and Feedback Loops

LED driver ICs often incorporate control signals for functions such as dimming or adjusting the output power. Pulse - width modulation (PWM) and analog dimming are two common techniques used for this purpose. PWM dimming rapidly switches the LED on and off at a high frequency, varying the duty cycle (the proportion of time the LED is on) to control the average current and thus the brightness. Analog dimming, on the other hand, involves continuously adjusting the voltage or current supplied to the LED.

Feedback loops play a vital role in maintaining the stability of the LED operation. The LED driver IC constantly monitors the actual current or voltage at the LED and compares it to the desired setpoint. If there is a deviation, the IC adjusts its output to correct the difference. For example, if the current flowing through the LED starts to increase due to a change in the load or input voltage, the feedback loop detects this increase and prompts the IC to reduce the output current, bringing it back to the desired level. This closed - loop control system ensures that the LED operates consistently, even under varying conditions.

Types of LED Driver ICs

Linear LED Driver ICs

Linear LED driver ICs are characterized by their simplicity and relatively low - cost design. They operate by dissipating excess voltage as heat, which makes them suitable for low - power applications where precise current control is required. One of the significant advantages of linear LED driver ICs is their low electromagnetic interference (EMI). This makes them ideal for use in small - scale consumer electronics, such as portable flashlights, bicycle lights, or some specialized lighting fixtures where EMI could interfere with other electronic components.

However, linear LED driver ICs also have limitations. Their efficiency is generally lower compared to other types of drivers, especially in high - power applications. The heat dissipation caused by the voltage regulation process can lead to increased power losses and may require additional heat - sinking measures. This makes them less suitable for large - scale or high - power LED lighting systems where energy efficiency and heat management are critical factors.

Switch - Mode LED Driver ICs

Switch - mode LED driver ICs use switching elements, such as transistors, to rapidly turn the power on and off, achieving high efficiency levels, often exceeding 90%. They can be classified into different types based on their voltage conversion capabilities. Buck (step - down) drivers are used when the input voltage is higher than the required output voltage, such as in driving LED strips with lower voltage requirements. Boost (step - up) drivers are employed when the input voltage is lower than the desired output voltage for the LEDs. Buck - boost drivers offer the flexibility to step up or step down the voltage, making them suitable for a wide range of applications.

The benefits of switch - mode LED driver ICs include their high efficiency, ability to handle high power levels, and flexibility in voltage and current regulation. They can be used in a variety of applications, from LED - based signage and display backlighting to industrial and automotive lighting. However, they also come with some drawbacks. The switching action can generate higher electromagnetic interference, which may require additional shielding or filtering to comply with electromagnetic compatibility (EMC) standards. Additionally, the design of switch - mode driver ICs is more complex compared to linear drivers, which can increase the cost and design challenges.

AC - DC LED Driver ICs

AC - DC LED driver ICs are specifically designed to interface directly with the AC mains power supply. These driver ICs often incorporate features such as power factor correction (PFC). PFC improves the efficiency of power usage from the grid by making the current waveform more in phase with the voltage waveform, reducing reactive power and minimizing power losses. AC - DC LED driver ICs also come with protection mechanisms against voltage surges, electrical faults, and over - current conditions.

They are commonly used in large - scale lighting systems, such as streetlights, commercial building lighting, and industrial lighting. In these applications, they can drive multiple LEDs or LED arrays, providing a reliable and efficient power supply. The ability to directly connect to the AC mains makes them convenient for installation and operation in various lighting environments, eliminating the need for additional power conversion stages in some cases.

LED driver IC Key Features and Functionalities

Dimming Capabilities

LED driver ICs support different dimming techniques to adjust the brightness of the LEDs. PWM dimming is a popular method that offers precise control over the brightness level. By rapidly switching the LED on and off at a high frequency, PWM dimming can create the illusion of a continuously variable brightness without significantly affecting the color quality of the LED. Analog dimming, on the other hand, provides a more continuous adjustment of the voltage or current, but it may be more prone to variations in color temperature as the brightness is changed.

Each dimming method has its own advantages and disadvantages. PWM dimming is often preferred in applications where flicker - free dimming is essential, such as in display backlighting or high - end lighting fixtures. Analog dimming, while simpler in some respects, may not be suitable for applications where color consistency is critical. The choice of dimming method depends on the specific requirements of the LED lighting application.

Protection Features

LED driver ICs are equipped with various protection features to safeguard the LEDs and the overall lighting system. Over - current protection detects when the current flowing through the LEDs exceeds a safe limit and either shuts off the output or limits the current to prevent damage to the LEDs. Over - voltage protection ensures that the voltage supplied to the LEDs does not rise to a level that could cause breakdown or premature failure. Under - voltage protection monitors the input or output voltage and takes appropriate action if the voltage drops below a specified threshold.

Thermal protection is another crucial feature. As LEDs and driver ICs generate heat during operation, excessive temperatures can degrade their performance and lifespan. Thermal protection mechanisms monitor the temperature of the driver IC or the LEDs and, if the temperature exceeds a safe threshold, reduce the output power or shut off the system to prevent overheating. These protection features enhance the reliability and longevity of LED lighting systems, reducing the risk of failures and the need for frequent maintenance.

Efficiency and Power Management

The efficiency of an LED driver IC is a key factor in determining the overall energy consumption of the LED lighting system. Efficiency is affected by various factors, including the type of conversion topology (linear, switch - mode), component losses, and operating conditions. Switch - mode LED driver ICs generally offer higher efficiency compared to linear drivers, especially in high - power applications.

LED driver ICs also incorporate power management features to further enhance energy efficiency. Standby modes reduce the power consumption of the driver IC when the LEDs are not in full operation, such as during periods of low activity or when the lighting system is dimmed. Energy - saving functions can be programmed to adjust the output power based on ambient light levels or occupancy sensors, ensuring that the LEDs consume only the necessary amount of power. These power management features not only contribute to cost savings but also make LED lighting systems more environmentally friendly.

Applications of LED Driver ICs

General Lighting

In residential lighting, LED driver ICs are used in a wide range of fixtures, from ceiling lights and table lamps to recessed lighting. For these applications, features such as smooth dimming and compatibility with standard light switches are essential. Homeowners often prefer the ability to adjust the brightness of their lights to create different moods and atmospheres. LED driver ICs with PWM dimming capabilities can provide flicker - free and precise dimming, enhancing the user experience.

In commercial lighting, factors such as color rendering, energy efficiency, and long - term reliability are of utmost importance. LED driver ICs play a crucial role in ensuring that LEDs in office lighting, retail store lighting, and hospitality lighting deliver consistent and high - quality illumination. They also enable the integration of energy - saving features, such as occupancy - based dimming and daylight harvesting, which help commercial establishments reduce their energy consumption and operating costs.

Automotive Lighting

LED driver ICs are widely used in automotive applications, including headlights, taillights, interior lighting, and dashboard displays. In automotive lighting, high - reliability is non - negotiable, as the lighting system must function flawlessly in various driving conditions. LED driver ICs need to be resistant to vibration, temperature variations, and electrical interference. They also must comply with strict automotive industry standards and regulations regarding safety, performance, and electromagnetic compatibility.

For example, in automotive headlights, LED driver ICs ensure that the LEDs produce a bright and consistent light output, providing optimal visibility for the driver. In dashboard displays, precise dimming control is required to ensure that the display is clearly visible in different lighting conditions, from bright sunlight to complete darkness.

Display Backlighting

LED driver ICs are essential for LCD and OLED display backlighting in devices such as smartphones, tablets, laptops, and televisions. In these applications, precise dimming control is crucial to enhance the visual quality of the display. The ability to adjust the backlight brightness accurately allows for better contrast, reduced power consumption, and improved battery life in portable devices.

Uniformity of light output is also a key requirement in display backlighting. LED driver ICs use advanced control algorithms to ensure that all the LEDs in the backlight module emit light with the same intensity, eliminating any visible brightness variations or hotspots. Additionally, low - power operation is highly desirable, especially in battery - powered devices, to extend the usage time between charges.

Industrial and Outdoor Lighting

In industrial lighting, such as factories, warehouses, and manufacturing facilities, LED driver ICs must be able to handle high - power loads and operate reliably in harsh environments. These environments may be subject to dust, moisture, extreme temperatures, and electrical noise. LED driver ICs with robust protection features and high - efficiency ratings are preferred to ensure long - term performance and minimal maintenance requirements.

Outdoor lighting, including streetlights, stadium lighting, and landscape lighting, also relies on LED driver ICs. Weather resistance is a critical factor in outdoor applications, as the driver ICs need to withstand rain, snow, and UV radiation. Long - term reliability is essential, as outdoor lighting systems are often difficult to access for maintenance. Additionally, features such as remote control capabilities are becoming increasingly important in outdoor lighting, allowing for easy adjustment of brightness, on/off scheduling, and monitoring of the lighting system from a central location.

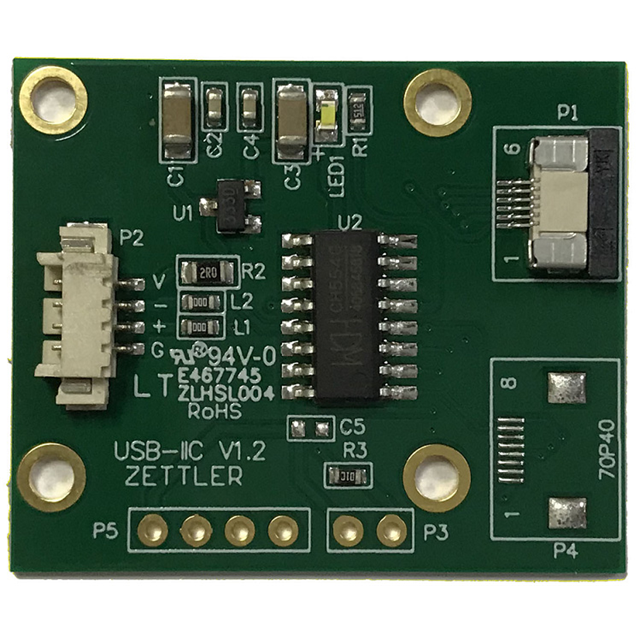

SIC is a trustworthy supplier and distributor of LED driver ICs. Our online store offers a rich variety of products, covering various types of LED driver ICs such as linear, switch - mode, and AC - DC ones, with reliable quality. Meanwhile, the store features a user - friendly interface, reasonable pricing, and fast delivery. We also provide comprehensive services for our partners, making us an excellent choice for procurement. Here are some recommended LED driver chips for you:

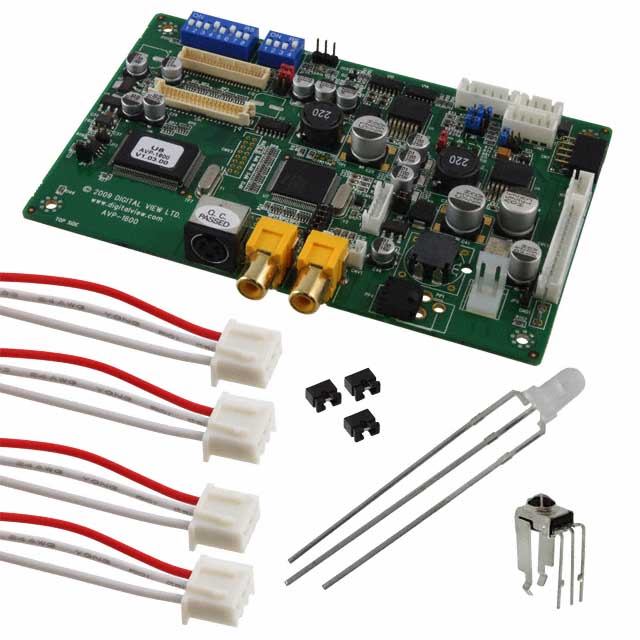

FL7733AMX LED Driver IC https://www.sic-components.com/product/product?product_id=4780840

Manufacturer: ON Semiconductor.

Features: It belongs to an AC-DC offline switching type LED driver chip, with multiple topological structures including flyback, step-down, and step-up modes. The installation type is SMT. The power supply voltage is 30V, the operating temperature range is from -40°C to +125°C, the output voltage is from 1.5V to 5V. It adopts the SOIC8_150MIL package, has a single-channel output, and supports the analog dimming function.

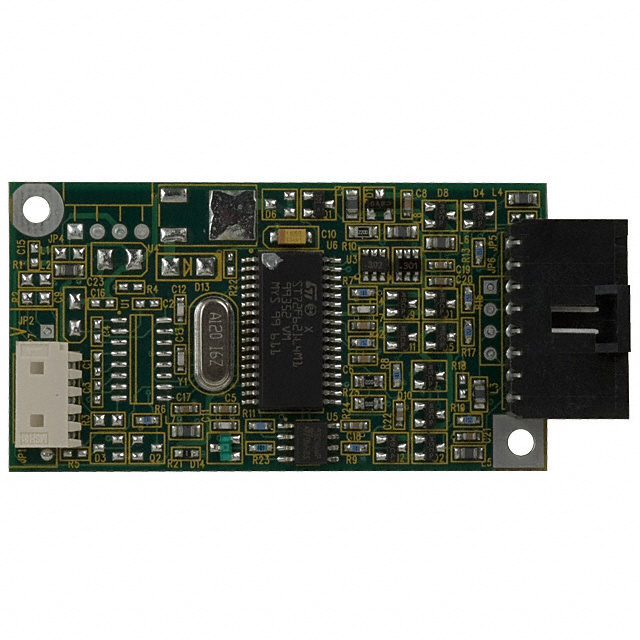

RT9293BGJ6 LED Driver IC https://www.sic-components.com/product/product?product_id=4146449

Manufacturer: Richtek.

Features: It is a high-frequency, asynchronous Boost converter and a step-up LED constant-current drive controller. The input voltage range is 2.5V - 5.5V. It integrates a power MOSFET switch internally and supports backlight applications with up to 10 series-connected WLEDs and OLED power supply. The operating frequency is 1MHz, allowing the use of small components, which helps to simplify EMI issues. It provides overvoltage protection with options of 50V and 50V/20V. It has a soft-start function, and the optional packages are TSOT-23-6 and WDFN-8L 2x2, which are convenient for achieving a balance between PCB space and overall cost.

https://www.sic-components.com/motors-actuators-solenoids-and-drivers

Hot Products

View MoreRelated Blogs

2000+

Daily average RFQ Volume

30,000,000

Standard Product Unit

2800+

Worldwide Manufacturers

15,000 m2

In-stock Warehouse

Wishlist (0 Items)

Wishlist (0 Items)